Manipulating sound waves without acoustic materials

Sound waves manipulation covers a wide range of physical phenomena such as absorption, reflection, transmission, diffusion, etc. Usually, these processes rely on a material interface, within which physical transformation of incident sound waves may occur at the mesoscopic scale (in the range of micrometers). For example, sound absorption occurs in porous materials, inside which networks of thin connected pores channel the fluid movements, resulting in friction losses that eventually make the sound energy vanish.

Up to now, it was strictly impossible to envision such a mechanism happening without an intermediate material.

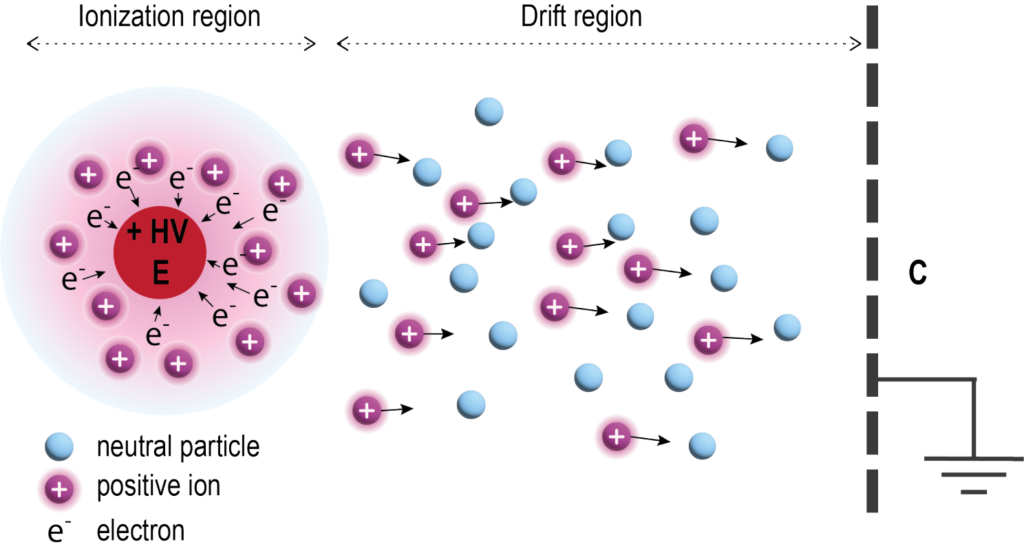

Here, we demonstrate how a plasma (layer of ionized air) can achieve such acoustic manipulation in a somewhat ethereal manner.

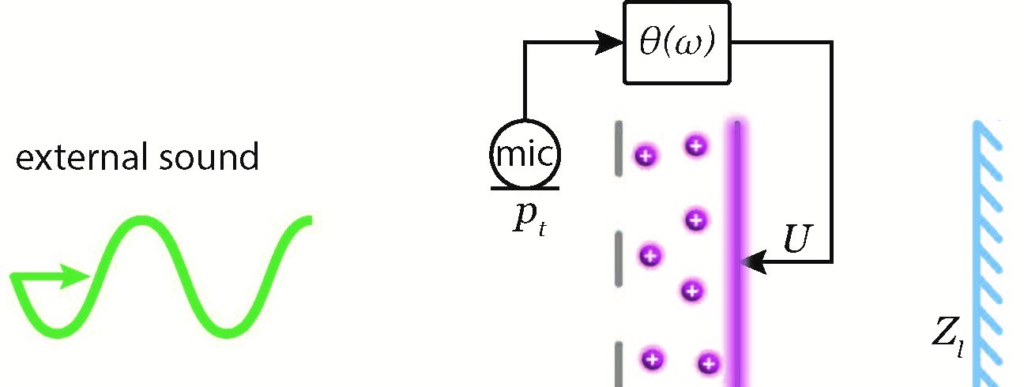

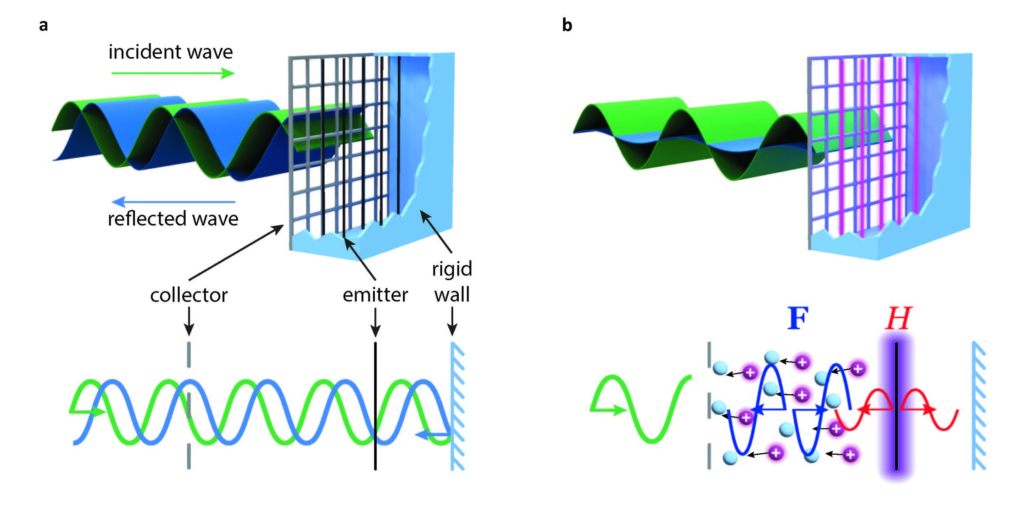

The proposed plasmacoustic metalayer consists of an ultrathin volume of ionized air between two partially open electrodes (the grounded “collector” grid electrode and the high-voltage “corona” wire electrode), capable of generating sound waves to interact with the sourrounding medium.

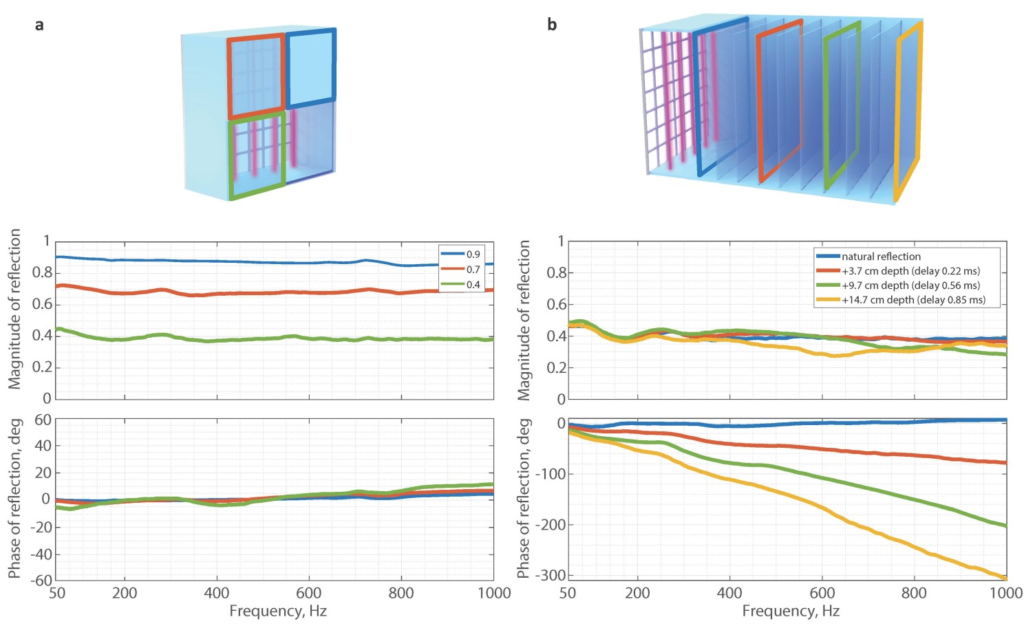

In this work, the plasmacoustic metalayer is associated with an active control hardware, comprising a control microphone and a digital controller that drives the active plasmacoustic metalayer in response to an external sound wave.

Unprecedented acoustic performance!

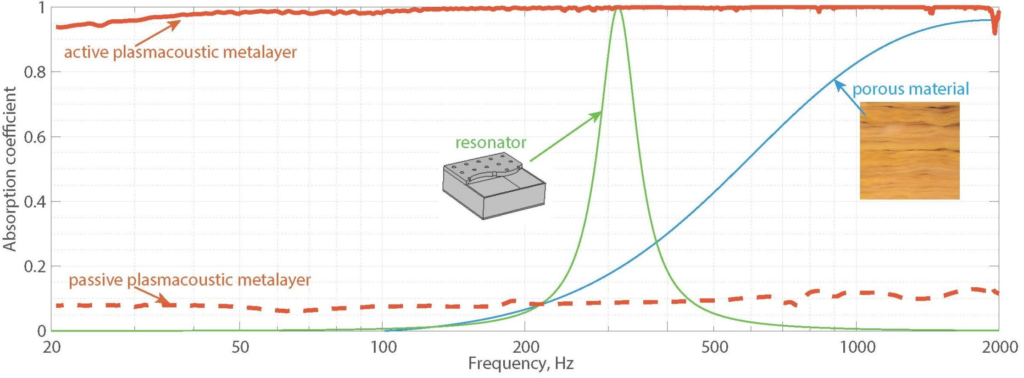

With this setup, we succeeded in achieving perfect sound absorption (more than 95% of the incident sound energy), over a broad frequency range (from less than 20 Hz up to 2 kHz). We have also demonstrated variable sound reflection (as a semi-transparent acoustic mirror). We have also been able to artificially delay the reflected sound as if the wall was virtually located further than its actual position.

It is worth noting that the effective size of the plasmacoustic metalayer (6 mm) is way much smaller than the wavelengths of interest, breaking the vexing “quarter-wavelength rule” down to 20 Hz!

(source: https://doi.org/10.1038/s41467-023-38522-5)

This work paves the way to a new generation of acoustic devices aiming at manipulating sound without using a material interface, and in a broadband manner.

This work has been published by Nature Communication in open access (Sergeev, S., Fleury, R. & Lissek, H. Ultrabroadband sound control with deep-subwavelength plasmacoustic metalayers. Nat Commun 14, 2874 (2023).

Further reading

- S Sergeev et al, J. Phys. D: Appl. Phys. 53 495202 (2020), doi: 10.1088/1361-6463/abafde

- S Sergeev et al, Acta Acust. 6 ,5 (2022), doi: 10.1051/aacus/2022001